Mach One Solutions is actively partnering with local communities and universities to promote aerospace education and innovation.

By hosting workshops, offering internships, and collaborating on research projects, Mach One provides hands-on learning opportunities for the next generation of aerospace engineers.

ESI Group Composites

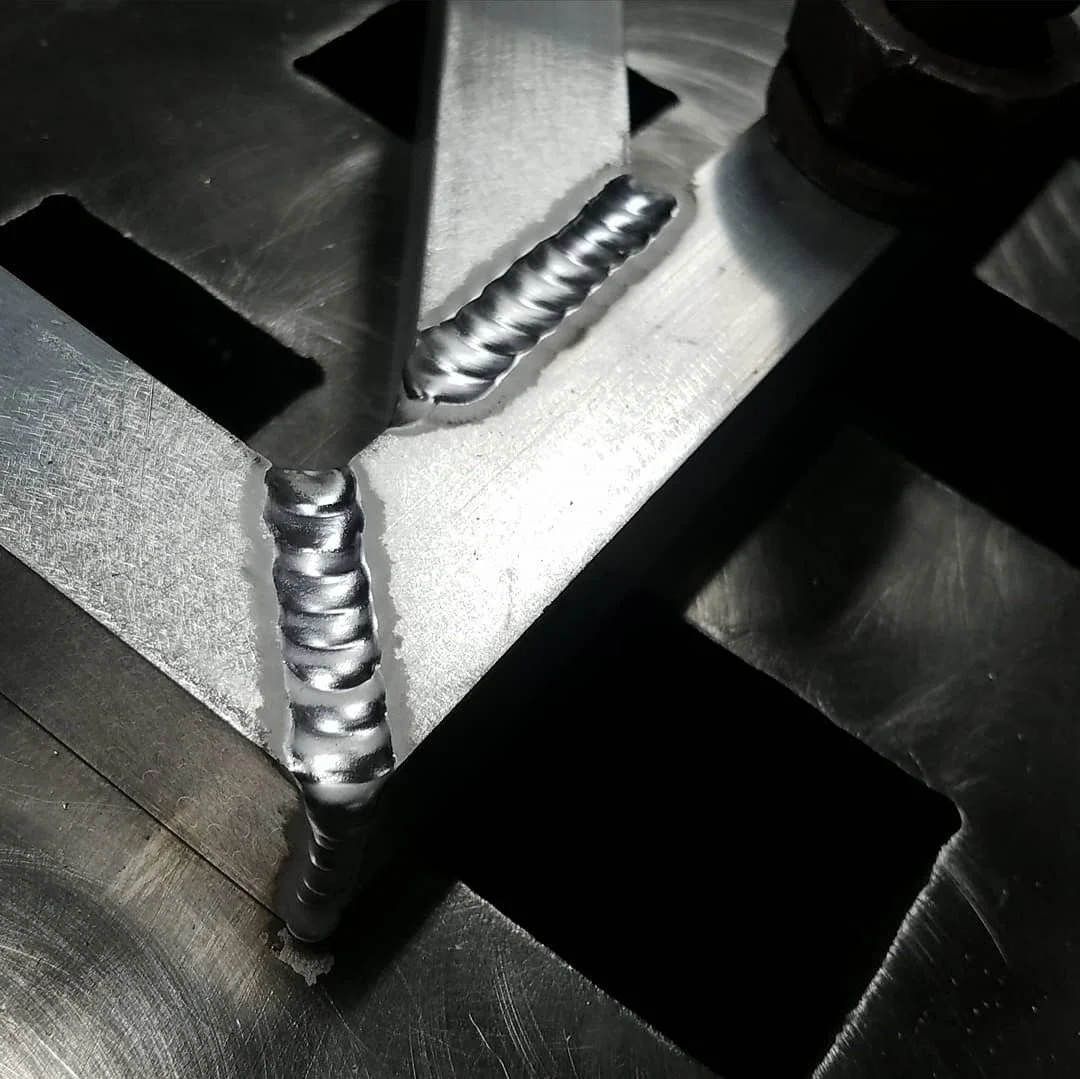

Mach One Solutions works with ESI PAM-COMPOSITES allows us to simulate every step of the composite manufacturing process, from cutting and draping

plies to modeling distortions during curing, demolding, machining, and assembly. With this tool, we address challenges in forming and thermoforming, resin injection and infusion, and post-machining. Through rapid iteration, we can quickly identify the root causes of manufacturing defects, helping reduce development time and costs for our customers.

How we use ESI Products to help you

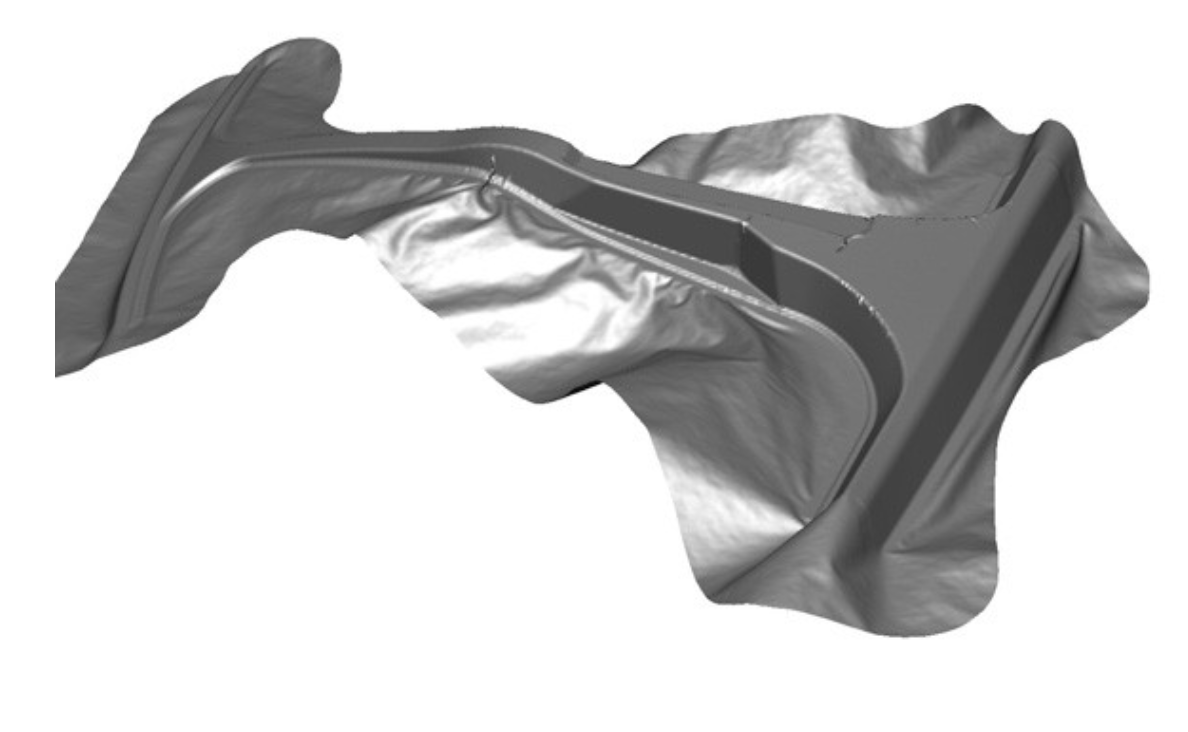

PAM-FORM, the composite forming simulation module within PAM-COMPOSITES, is used to simulate the pre-forming process of dry textiles or the thermoforming process of fiber-reinforced composite materials made of thermoset or thermoplastic resins (organosheets, GFRP, CFRP…).

PAM-FORM allows you to model a wide range of processes including:

stamping using two rigid molds

rubber pad forming

diaphragm forming

and more

PAM-RTM, the resin molding software module within PAM-COMPOSITES, is used to simulate the resin injection or the resin infusion of a preform.

PAM-RTM can model a wide range of processes including:

Resin Transfer Molding (RTM)

Vacuum Assisted Resin Infusion (VARI)

Compression RTM (CRTM)

High-Pressure RTM (HP-RTM)

and many more

This module predicts how the resin flows in a preform that might include inserts (metals, wood, foam).

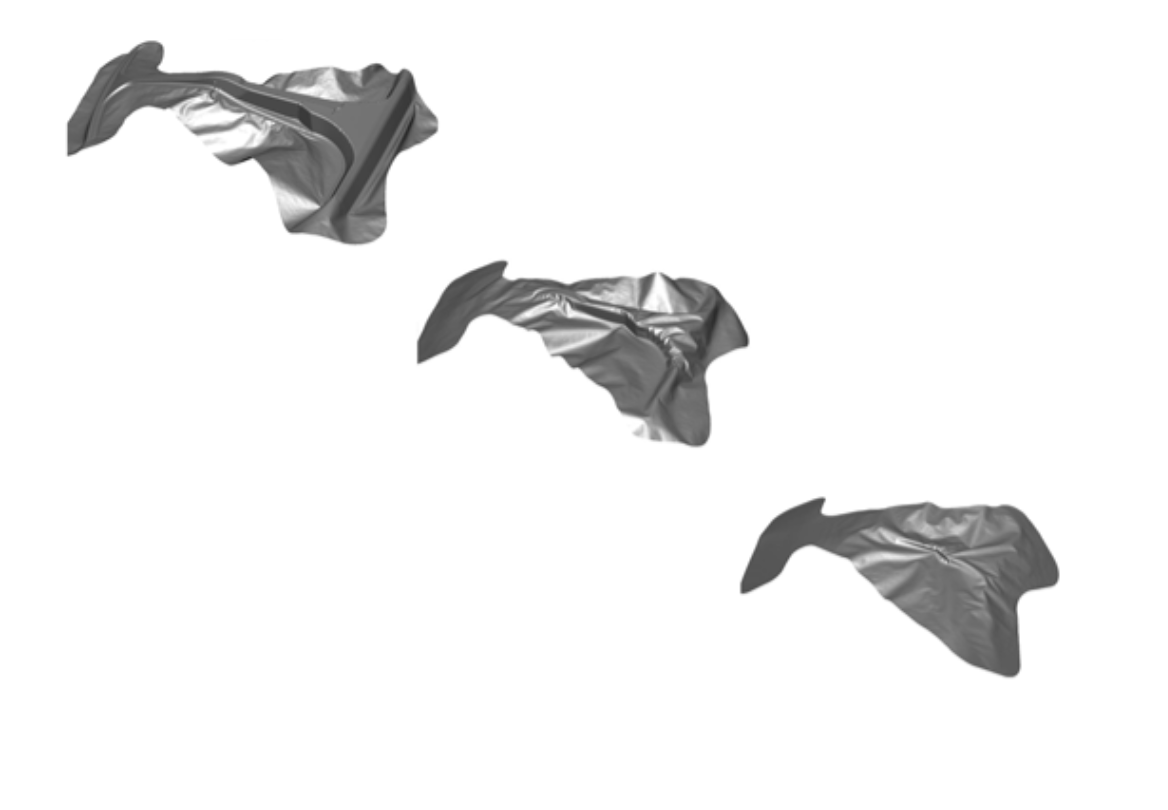

PAM-DISTORTION, predicts manufacturing-induced residual stresses and resulting geometrical distortions of produced composite parts. During manufacturing, composite parts made of thermoset matrix go through a curing operation that transforms the resin from a liquid to a solid-state. This thermo-chemical process results in residual stresses that will distort the part.

With ESI PAM-COMPOSITES, analyze the curing process, optimize the curing cycle, and predict the curing time and the evolution of the temperature and degree of cure during the cycle.